Aluminum Wiring Remediation

Aluminum Wiring Remediation

When we debated about the convenience of buying a house with aluminum wiring, we considered that if we plan an aluminum wiring remediation process, we would not have any problem buying the house, even with an FHA loan, or selling it. The reason is that after this aluminum wiring remediation we will be passing the electrical chapter of any conventional appraisal or FHA inspection. Therefore, we are going to deal with this process without delay.

Certain properties of aluminum can cause deterioration of connections, possibly presenting a fire hazard after years of service. A fundamental principal of electrical safety for wiring is that high temperatures are hazardous. The hazard lies in the overheating of connections, typically after carrying a heavy electrical load, such as a hair dryer or portable heater.

Every connection of aluminum-to-aluminum or aluminum-to-copper wire in your building should be repaired in order to obtain the maximum benefit of the repair work. Appliances connected directly to 12 and #10 AWG aluminum branch circuit wiring (i.e. dishwashers, cooking equipment, heaters, air conditioners and light fixtures) must be repaired in addition to wall outlets, switches, junction boxes,

and panel boxes.

Aluminum wiring is still permitted and used for certain applications, including

residential service entrance wiring and single-purpose higher amperage circuits such as 240V air

conditioning or electric range circuits.

All electrical modifications and additions must be in accordance with local regulations and inspected by

municipal authorities.

Aluminum Wiring Remediation Options

| Method | Description | Results | Cost |

| TOTAL REWIRE | Replace the home’s aluminum wire with copper wire. | The most sure and permanent solution. | Highest (usually prohibitive) |

| COPALUM CRIMP | A type of pigtail connection whereby copper is “crimped” with the existing aluminum. This method is recommended by the National Fire Protection Association, UL and the US Consumer Products Safety Commission. | If every connection is corrected this way, it is considered a complete and permanent repair. | High |

| REPLACE | If the outlets and switches are aging, or not marked CO/ALR, replace them with CO/ALR approved devices. | Greatly reduces the most frequent failures. Less permanent than rewiring or COPALUM crimp. | Moderate |

| TIGHTEN | All connections should be abraded to remove the existing oxidation, immediately covered with an non-flammable anti-oxidant and then tightly reconnected. | This is not a permanent correction. Re-tightening must re-occur every year or two. | Low |

| LEAVE IT ALONE | If no signs of trouble exist, repairs can be postponed. Periodic examination by a qualified electrician is recommended. | Consider this choice as buying (or borrowing) time. | Lowest |

Let´s see now all the options from the table above, one by one.

Rewire The House

The definitive answer to aluminum wiring worries is to eliminate the primary cause: get rid of the aluminum wire itself. Depending upon the architectural style of your home and the number and locations of unfinished spaces it may be relatively easy to rewire your home. The cost and disruption of doing the job depends greatly upon the construction of the house. A good crawl space or basement and a good attic make the job much easier. If remodeling is contemplated, either complete or in part, by all means replace any aluminum wiring in the area. Consider upgrading or replacing the service entrance at the same time, since it is probably thirty to forty years old and a bit small by today’s standards.

COPALUM Crimping

Since it is often impractical to rewire some types of aluminum wired homes, or since rewiring may be prohibitively expensive for some homes (e.g. split or multi-levels with no unfinished areas).

The US Consumer Product Safety Board concluded a permanent repair must permit the repair of every connection to, or splice between, aluminum wire in the home.

The repaired connections must be permanently repaired and must result in a system that can be maintained without the need for special switches, wall outlets or other connectors.

The repair technique must be practical for use in an occupied and furnished home.

The US Consumer Product Safety Commission-sponsored research, laboratory tests, and demonstration projects identified only one method of repairing existing aluminum wire circuits which meet these criteria. That repair is known as the COPALUM crimp connector repair.

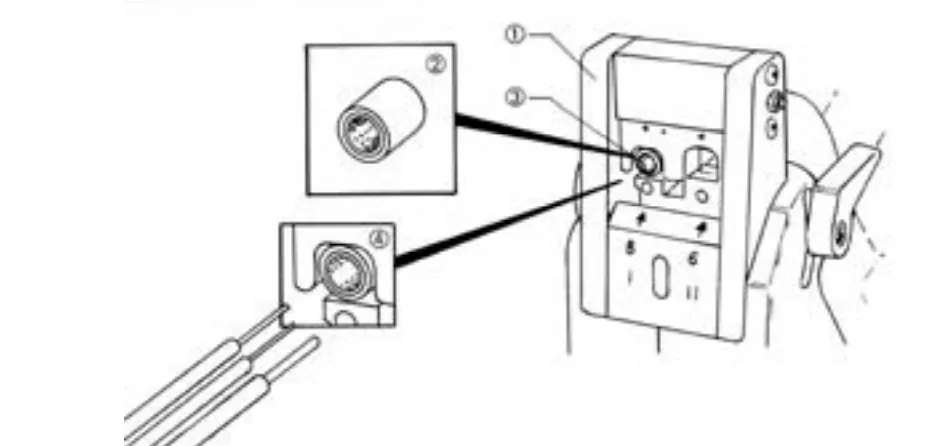

The crimp connector repair consists of attaching a piece of copper wire to the existing aluminum wire branch circuit with a specially designed metal sleeve and powered crimping tool. The metal sleeve is called a COPALUM parallel splice connector and is manufactured only by AMP Incorporated (a division of TYCO). This special connector can be properly installed only with the matching AMP tool. This tool makes a permanent connection that is, in effect, a cold weld. An insulating sleeve is placed around the crimp connector and heat-shrinked to complete the repair.

Replace The Outlets And Switches

The other repair recommended by the industry uses switches and outlets labeled “CO/ALR”. Underwriters Laboratories Inc. (UL) lists these devices especially for use with aluminum wire, although they can be used with copper or copper-clad wire. CO/ALR devices perform better with aluminum wire when installed carefully and according to best electrical practices than do the types of switches and outlets usually used in the original installations of old technology aluminum branch circuit wiring. However, CO/ALR connectors are not available for all parts of the wiring system (for example, for permanently-wired appliances and ceiling mounted light fixtures, GFCI outlets, etc). CO/ALR devices must be considered to be, at best, an incomplete repair. Further, CO/ALR wiring devices have failed in laboratory tests when connected to aluminum wire typical of that installed in existing homes. The test conditions simulated actual use conditions; no “overstress” type of testing was used.

NOTE: If you have an aluminum wire termination in your home which exhibits symptoms of failure, twist-on connector pigtails or CO/ALR devices may be used as an emergency temporary repair for a failed aluminum termination. Should such a repair be performed, it is recommended that you arrange to have your home rewired or the COPALUM crimp connector repair performed as soon as possible.

Many homes still have the original wiring devices, and these stand a good chance of being the CU-AL type or the unmarked type. They are also getting pretty old, so that receptacles may be having trouble gripping plugs, and switches may be failing. Bending and handling of the wire should be kept to a minimum. The wire at each connection should be cleaned of oxidation, and non-flammable, anti-corrosion paste should be applied. This is not a do-it-yourself project when aluminum wire is involved.

Tighten and Check All Connections

Although not considered a permanent repair, tightening all the aluminum connections can buy you some time while reducing the hazard. As was noted earlier, aluminum contracts and expands at a much greater rate than copper wire causing hazardous spacing between the wire and connection. Arcing can occur and if combustible material (accumulated dust, dirt debris) is present a fire may occur.

This procedure entails stripping the insulation off of the wire or abrading the exposed wire (if the amount of wire present in the box is limited) the wire is completely coated with a non-flammable oxide inhibitor to prevent any further oxidation. Then a new connection is made that ensures a tight connection. All visible dust and dirt should be removed and at that point this connection should be safe for a year or two.

Regardless of the method chosen for dealing with outlets and switches, the connections in the circuit breaker panel and at all junction boxes should be checked. At the circuit breaker panel, verify that each aluminum wire is coated with corrosion inhibitor. Apply the specified torque to each screw terminal to make sure it has not loosened. When re-making a connection remember to abrade the wire to remove the aluminum oxide layer and immediately apply corrosion inhibitor before re-connecting.

Leave It Alone

Sometimes it is best to leave things alone, and other times one can’t get away with leaving things alone. If the aluminum wiring is in good condition, the latter, not the former, may apply. If you are trying to avoid the repairs for a while, have an electrician who specializes in aluminum wiring repairs inspect some heavily used circuits, then repeat the process once a year. Aluminum wiring in good condition is better off left undisturbed. Load testing and inspection of the devices for the CO/ALR marking can be done without perturbing the wiring. Consider this option a postponement of the inevitable.

XXXX

There is one method that is the rewiring of the connections: from aluminum wiring to copper.

Aluminum wiring was used extensively in homes built between 1969 – 1976. Aluminum was chosen over copper because of price. Copper prices were at an all-time high. The construction industry was looking for cheaper materials and aluminum wire was the next best conductor available.

Aluminum wiring on its own is not dangerous. The problem lies with the connection or junction points. It just requires special connectors, but those connectors can oxidize or rust.

When these connection points oxidize, the connection becomes weak causing electrical hazards and possibly fire. If you have aluminum wiring, you can deal with it without replacing your wiring. Rewiring your home can cost thousands of dollars, but by using a process called pig-tailing, the concerns of aluminum wiring can be resolved. Pig Tailing refers to a process whereby you attach a 6 inch copper wire to the end of the existing aluminum wire and attach it to the wire using a special marrette (connector).

The common connector you can buy at your local home improvement store is not rated for this. Using these standard connectors is wrong and you will fail your house inspection. What you need is a special type of marrette (connector) that is for use with mixed materials (aluminum and copper).

It is recommended to use a licensed electrician to do aluminum to copper pig tailing. Hiring a licensed electrician can ensure that any other electrical issues can be spotted and rectified quickly. This can save you the extra labor costs of a separate service call later.

Contact your insurance provider to check their policies, most insurance companies are refusing to insure homes with aluminum wiring. Hiring a licensed electrician to perform the remediation and inspection ensures it meets all current electrical codes in your area. This satisfies most insurance providers and the home can then be insured.

If you do the work yourself, you can’t get certification required by insurance companies.

The First Step Is To Identify Aluminum Wiring In A property

Identifying the aluminum-wiring hazard is the first step towards fixing the problem. The following simple

steps can be taken to assist you in determining if aluminum wiring is present: (It is recommended that a

licensed electrician make the determination)

- Determine when was the building or house built or re-wired, or when new circuits added?

Buildings built, rooms added, circuits rewired or added between 1965-1973 may contain

aluminum wiring. - Don’t assume that there’s no aluminum wire if your building was not built during these years.

Circuits may have been added, extended, or modified using aluminum wiring. Or an installer

may have had leftover aluminum wire and used it after these dates. - Don’t assume there’s no aluminum wire just because you find none in the panel. Aluminum

may have been used for part of circuits or for some but not other circuits in the building. - At outlets and switches, look at stripped wire ends. Oftentimes, simply removing the cover

plate will give sufficient view. Be especially cautious if you see back-wired receptacles. It may

be difficult to see if the wire is aluminum, but if it is, the smaller wire contact surface when this

method was used may increase the risk of overheating or other failures. - Look at wire at circuit breakers in the electric panel for aluminum wire. The electrician will notice bare silver-colored wire visible at the circuit breaker. The aluminum wire could simply be present in a single circuit installed between two copper wires located on adjacent breakers.

- Look for the word “Aluminum.” Look for printed or embossed letters on the plastic wire jacket where wiring is visible or at the electric panel. Some aluminum wire has the word “Aluminum” or a specific brand name such as “Aluar”, “Kaiser Aluminum” plainly marked on the plastic wire jacket. Some white colored plastic wire jackets are inked in red; others have embossed letters without ink and are hard to read. Try shining a light along the wire.

- In an area where the wire is visible, such as an attic, look at the wire gauge or “size.” Look for #12-gauge wires in the attic or other places where wiring is readily available. If you see only #12 and no #14, look further. Aluminum wire must be one wire gauge size larger for a given circuit than if copper was used. So while #14 copper wire is permitted on a 15-amp electrical circuit, if aluminum wire was used for the same circuit it would have to be #12. Similarly, a 20- amp circuit uses #12 copper wire or #10 aluminum wire. Common residential lighting and electrical-receptacle circuits are 15-amp or possibly 20-amp (e.g., in a kitchen). So if you see only #12 or larger wires in the attic of your house look further to see if it’s aluminum. The wire gauge size is printed or embossed on the wire jacket. #12 does not guarantee it’s aluminum, it’s just more data to point in that direction.

- Look at bare wire exposed at the neutral bus. An easy place to look for aluminum wiring

(other than at the circuit breakers) might be at the neutral bus where both white neutral wires

and ground wires are connected in a row. At the neutral bus it’s easier to see exposed portions

of the wire itself.

Accepted Aluminum Wiring Remediation Processes

Aluminum wiring can be replaced or

repaired to effectively and permanently reduce the possibility of fire and injury due to

failing (overheating) wire connections and

splices. It is highly recommended that you

hire a qualified electrician to perform this

remediation.

Other than complete replacement of aluminum wire with copper wire, there may be numerous potential solutions for the

permanent repair of hazardous aluminum

wire connections and splices. However,

CPSC can recommend repair methods or

products only where there is satisfactory,

documented evidence that the methods or

products meet the following criteria:

• Safe. The method or product must be

safe and not increase the risk of fire or

other hazards.

• Effective. The method or product must

be effective and successfully eliminate or

substantially mitigate the fire hazard.

• Permanent. The method or product

must affect a permanent repair. Methods

or products designed to address temporary or emergency repair situations, but

which may fail over time, are not considered permanent.

Based on these standards, as of the date

of this publication, CPSC approves of only

three methods for a permanent repair.

1) Complete Replacement of Copper

Cable

2) COPALUM Method of Repair

3) Acceptable Alternative Repair

Method/AlumiConn Connector

Complete Replacement with Copper

Cable

Replacement of the aluminum branch circuit conductors with copper wire eliminates

the primary cause of the potential hazards,

the aluminum wire itself. Depending on

the architectural style of your home and

the number and locations of unfinished

spaces (e.g., basements and attics), it may

be relatively easy for a qualified electrician

to rewire your home. A new copper wire

branch circuit system would be installed,

and the existing aluminum wire could be

abandoned inside the walls. This is the best

method available; but for many homes,

rewiring with copper is impractical and/or

prohibitively expensive.

COPALUM Crimp Method of Aluminum Wiring Remediation

As an alternate to rewiring with copper,

CPSC recommends attaching a short

section of copper wire to the ends of the

aluminum wire at connection points (a

technique commonly referred to as “pigtailing”), using a special connector named

COPALUM to join the wires. CPSC staff

considers pigtailing with a COPALUM connector to be a safe and permanent repair of

the existing aluminum wiring. The repair

should include every connection or splice

involving aluminum wire in the home, including outlets, dimmers, switches, fixtures,

appliances, and junction boxes. The repaired system, with short copper wire extensions at every termination throughout the

home, permits the use of standard wiring

devices, including receptacles and switches.

The COPALUM repair method is recommended by CPSC on the basis of CPSC sponsored research, laboratory tests, and

demonstration projects. This repair method

has been thoroughly proven by more than

a quarter of a century of field experience to

provide a permanent, low-resistance electrical connection to aluminum wire. The

COPALUM repair method eliminates the

aluminum connection failure problems and

still uses the existing, installed aluminum

wire. The COPALUM repair method has

been shown to be practical for installation

in an occupied and furnished home.

Every connection of aluminum-to-aluminum or aluminum-to-copper wire should be

repaired in order to obtain the maximum

benefit from such repair work. All appliances connected directly to No.12 or No.10

AWG aluminum branch circuit wiring (e.g.,

dishwashers, cooling equipment, heaters,

air conditioners, and light fixtures) must be

repaired in addition to wall outlets, switches, junction boxes, and panel boxes.

The COPALUM connector is a specially

designed system that includes a metal sleeve

intended to be installed only with a dedicated power tool and crimping die to make

a permanent connection, that is, in effect,

a cold weld (the precision dies in the COPALUM tool compress the connector and

wires using upwards of 10,000 pounds of

force, as required to make the permanent

aluminum wire connection).

An insulating sleeve is placed around the

crimp connector to complete the repair.

The copper wire pigtail is then connected

to the switch, receptacle, or other termination device. An example of a repaired receptacle outlet is also illustrated below.

Acceptable Alternative Repair Method: AlumiConn

CPSC staff recognizes that copper replacement may be cost prohibitive and that the

COPALUM repair may be unavailable in

a locality. Based upon an evaluation that

was, in part, CPSC supported,5

consumers

are advised that, if the COPALUM repair

is not available, the AlumiConn connector

may be considered the next best alternative

for a permanent repair. This repair method

involves pigtailing using a setscrew type

connector instead of the COPALUM crimp

connector in the repaired connections.

The AlumiConn connector has performed

well in initial tests, but is too new to have

developed a significant long-term safe

performance history as the COPALUM

repair. The repair should be conducted by a

qualified electrician because careful, professional workmanship and thoroughness are

required to make the AlumiConn connector repair safe and permanent.

Connectors with Aluminum Wire

Remediation Methodologies That Are Not Recommended

Two other repair methods described

below are often recommended by some

electricians because they are substantially

less expensive than COPALUM crimp

connectors. CPSC staff does not consider either of these repairs an acceptable

permanent repair.

The use of electrical receptacles and switches marked COALR, CO/ALR, AL-CU or CU-AL have not

been recommended at this time by the US CPSC for aluminum wiring repairs

The first repair (“pigtailing”) involves attaching a short piece of copper wire to the aluminum wire with a twist-on connector sometimes called a wire nut; the copper wire is connected to the switch, wall outlet or other termination device. The Commission staff has evaluated the effectiveness of “pigtailing” as a repair. In CPSC-sponsored laboratory testing some brands of twist-on connectors have performed very poorly. Over time, substantial numbers of these connectors have overheated in laboratory tests. Surveys of statements made by electricians and electrical inspectors confirm the highly variable and often poor performance of these connectors when used with old technology aluminum wire. It is possible that some pigtailing “repairs” made with twist-on connectors may be even more prone to failure than the original aluminum wire connections. Accordingly, the Commission staff believes that this method of repair does not solve the problem of overheating present in aluminum branch circuits.

Twist-on Connectors

The first temporary repair involves

pigtailing with a twist-on connector. The

effectiveness of “pigtailing” using twist-on

connectors has been evaluated by CPSC

staff. In CPSC-sponsored laboratory testing

and life tests, substantial numbers of these

connectors overheated severely.

Surveys of and statements made by electricians and electrical inspectors confirm the

highly variable and often poor performance of twist-on connectors with aluminum

wire. It is possible that some pigtailing

“repairs” made with twist-on connectors may be prone to even more failures

than the original aluminum wire connectors. Accordingly, CPSC staff believes

that this method of repair does not solve

the problem of overheating present in

aluminum-wired branch circuits.

Is Not a Recommended Repair

“CO/ALR” Switches and Receptacles

The other repair recommended by the

industry is to use switches and receptacles

labeled “CO/ALR.” These devices are

intended for direct connection to aluminum wire, although they can be used with

copper or copper-clad wire. CO/ALR

devices perform better with aluminum

wire than non-CO/ALR devices when

installed carefully and according to best

electrical practices. However, CO/ALR

wiring devices have failed in laboratory tests

when connected to aluminum wire typical

of that installed in existing homes. The test

conditions simulated actual use conditions;

no “overstress” type of testing was used.

Further, CO/ALR connectors are not

available for all parts of the wiring system

(e.g., for the permanently wired appliances

and ceiling mounted light fixtures). In the

opinion of CPSC staff, CO/ALR devices

must be considered, at best, an incomplete

repair.

Recommendations on Temporary Repairs

AL/CU twist-on connector pigtails or

CO/ALR devices may be used as an emergency, temporary repair for a failed aluminum termination

Concerns Arounds Original Aluminum Wiring Installations

concerns related to the original installation (1965-

1972) of single-strand aluminum/solid aluminum wiring connected to the lower

branch circuits (receptacles, switches, lights and small appliances). Homes with

aluminum main service wires and heavier 240 volt circuits that feed major

appliances (e.g., dryers, ranges, air conditioners) are however different and require a different treatment.

Trouble Signs

Unfortunately, failing aluminum-wired connections seldom provide easily detected warning signs. Aluminum-wired connections and splices have been reported to fail and overheat without any prior indications or problems.

- Electrical receptacles, such as outlets and wall plugs, do not work

- Outlets, wall plugs, etc. have visible damage

- Switches, outlets, and wall plugs are warm to the touch

- Flickering lights

- Lights that are connected to the electrical system, but do not work

- Electrical junctions or connections are damaged

- Signs of scorching or overheating in the electrical system

If you notice any signs of a problem, have a qualified electrician determine the cause. DO NOT TRY TO DO IT YOURSELF. You could be electrocuted, or you could make the problem worse.

Signs of electrical system problems include hot-to-the touch face plates on receptacles or switches; flickering lights; circuits that don’t work; or the smell of burning plastic at outlets or switches.

When Was Aluminum Wiring Used?

The U.S. Consumer Product Safety Commission (CPSC) staff and other government officials have investigated numerous hazardous incidents and fires throughout the nation involving aluminum branch circuit wiring. A national survey conducted by Franklin Research Institute for CPSC showed that homes built before 1972, and wired with aluminum, are 55 times more likely to have one or more wire connections at outlets reach “Fire Hazard Conditions” than homes wired with copper.

The survey conducted by the Franklin Research Institute defined “Fire Hazard Conditions” to occur when receptacle cover plate mounting screws reached 149°C (300°F), or sparks were emitted from the receptacle, or materials around the receptacle were charred.

That survey encompassed only the wire connections at outlets. It did not address other types of aluminum wire connections and splices in homes that are also prone to fail. No information was developed for aluminum-wired homes built after 1972.

The fire hazard investigated by CPSC occurs at connections with aluminum wire, including receptacles or switches and junction boxes; or the hazards occur with major appliances, including dishwashers or furnaces, for example. There are several deterioration processes in aluminum wire connections that cause increased resistance to the flow of electric current, resulting in damage that is cumulative in effect.

That increased resistance causes overheating, sometimes at hazardous levels, when current is flowing in the circuit. A shortage of copper in the mid 1960s caused builders to increase the use of aluminum wire in residential electrical distribution systems from the few large-power circuits (i.e., for electric clothes dryers and ranges), to general purpose 15- and 20-ampere-rated circuits.

Homes built before 1965 are unlikely to have aluminum branch circuit wiring. Electrical cables installed between 1965 and the mid 1970s in new homes, in additions, and as part of rewired/new circuits may contain aluminum wiring. On April 28, 1974, two people died in a home in Hampton Bays, N.Y. Fire officials determined that the fire was caused by an overheating aluminum wire connection at a wall receptacle.

Electrical Inspection Required After The Completion Of The Aluminum Wiring Remediation Process

In all cases of aluminum branch wiring, insurers require that all aluminum

branch circuit wire connections to the service panel must have been inspected and

repaired as necessary to ensure neither corrosion nor oxidation is present and all

connections are tight, before the home can be insured.

An application for a home that has all aluminum branch wiring circuit connections

remediated using one of the methods accepted by CPSC, such as the complete rewiring, COPALUM crimp method, or AlumiConn connector, may be submitted to insurers for their underwriting.

To establish eligibility for coverage, documentation from a state-licensed electrician confirming that all aluminum-to-copper connections have been completely rewired, or more commonly, repaired via the COPALUM crimp method or the AlumiConn connector method must be submitted.

In addition, the property must meet all other eligibility requirements of course, such as for example, a foundation inspection, where in the checklist the crawlspace is under scrutiny for the appearance of puddles of water, if there are joists that would require reinforcement or sistering, sagging or sinking floors, and a long list outside the electrical domain.

Legal Indications From The NEC To Apply In An Aluminum Wiring Remediation Process

The CPSC research, as well as various other studies, led to code changes concerning the use of aluminum conductors.

One would think that with so many concerns associated with aluminum wiring, there would be stringent limits for its applications. In fact, aluminum wiring is addressed in only a few sections of the NEC. One of these sections simply identifies what types of aluminum alloys are allowed.

Prior to 1972, aluminum conductors (“old technology”) were made of many different types of alloys. The aluminum typically being used at that time had very large coefficients of thermal expansion. This meant that devices made from this substance would expand and contract a great deal over small temperature increments. The aluminum also had a high frequency of bending and creep failures.

The aluminum industry found that alloys using specific additives helped alleviate some of these mechanical problems. Alloys were identified that were stronger, more ductile and capable of numerous bending cycles without experiencing failure. The National Electric Code (NEC) was eventually amended to require that “Solid aluminum conductors No. 8, 10, and 12 shall be made of an AA-8000 series electrical grade aluminum alloy conductor material. Stranded aluminum conductors No. 8 through 1000 kc mil … shall be made of an AA-8000 series electrical grade aluminum alloy conductor material.”

Another section of the code states that, “Conductors of dissimilar metals shall not be intermixed in a terminal or splicing connector … unless the device is identified for the purpose and conditions of use.” How is a device identified for a specific purpose or use? The manufacturers of the products do this themselves.

If a company wants to make an aluminum-to-copper connector, it identifies it as such. Before most electrical inspectors will allow such a device to be used in an installation, they will make sure that it is listed with the Underwriters Laboratories Inc. (UL). The UL is an independent, not-for-profit organization, recognized as the foremost product safety certifying organization in the world. The UL conducts thorough testing and evaluations of a product before giving it a UL listing.

However, with twist-on aluminum wire connectors, independent tests by the CPSC and independent electrical consultants have indicated that these devices are prone to failures. One independent consultant, Dr. Jesse Aronstein, states that the UL testing standards do not adequately mirror conditions experienced in the field. He claims that when these products are tested under different conditions they have a high rate of failure. Subsequent field failures may help to substantiate these claims.

Symptoms That Indicate That Aluminum Wiring Remediation Is Required

The trouble with aluminum wiring is caused by bad connections, and the symptoms are the same as for bad connections in copper wiring. Observing any of these symptoms may indicate that the wiring needs attention, but will not, by itself, identify aluminum wiring. On the other hand, if you do have aluminum wiring, these signs will tell you that it is time for prompt action.

Incandescent lights may momentarily dim when a motor starts.

Incandescent lights may momentarily brighten when a motor starts.

Recurring flickering of incandescent lights often indicates a bad connection or lights that burn out very quickly.

Things suddenly stop working, and no circuit breakers have tripped.

Sparks, flame, smoke

Signs of overheating

- Hot to the touch electrical outlet or light switches

- Electrical circuit that does not work

- Flickering lights

- The smell of burning plastic at electrical receptacles

More often, the burn-out happens unobserved. Look for signs of soot or scorching around or behind the face plate. Soot deposited at the connection slots of a receptacle is usually caused by a worn-out receptacle rather than by bad connections.

An overheated connection, especially at receptacle or switch terminals can cause the metal face plate screws to become very hot — even too hot to touch. The face plate itself will also be warm. A slight warming of the receptacle and plug is normal with a heavy load like a hair dryer or portable heater. No parts should ever become too hot to touch.

Aluminum wires are better in electrical distribution and transmission. However, typical household wiring devices (GFCI, receptacle outlets, light switches, etc.) are not rated for aluminum wire. As a result, an aluminum wired house is more at risk to reach hazardous fire conditions at the outlet wiring connections rather than homes that are wired with copper wires.Unfortunately, electrical aluminum wires rarely show signs of deterioration. However, If you detect any of the following signs:

You potentially have an aluminum wire problem and you should contact a licensed electrician to address it. Do not try to do it yourself. You could get electrocuted or cause an electrical fire.The Consumer Product Safety Commission (CPSC) only recommends the following three methods to fix aluminum wire problems permanently

- Completely replace your home with copper wire

- Pigtail the aluminum wire ends with special crimp connectors called COPALUM

- Connect the aluminum wire ends with aluminum to copper AlumiConn wire lug connector

Rewiring your entire home with copper wire can be quite costly and impractical. As an alternative, the COPALUM and the AlumiConn methods are the most cost effective ways to address your aluminum wires.

The COPALUM and the AlumiConn methods consist of connecting copper wire to the end of the aluminum wire using a special COPALUM crimp connector or an AlumiConn wire lug connector. This process is often referred to as pigtailing. The repair must include all direct connections or splices involving aluminum wire in the home such as but not limited to electrical outlets, light switches, GFCIs, appliances, light fixtures and junction boxes. As a result, standard copper wiring devices (receptacles and dimmers) can now be safely connected to the home aluminum wires.The COPALUM method can only be administrated by a certified COPALUM electrician who has been trained by the special dedicated tool and crimping die manufacturer. Please visit tooling.tycoelectronics.com/copalum/copalum_home.asp to find a certified COPALUM electrician near your area. The tool will not be available to you unless you have been trained by the manufacturer.

The AlumiConn method is the most accessible and cost effective solution to addressing Aluminum electrical wiring issues. Unlike the COPALUM method, any certified electrician can repair your Aluminum wires with the AlumiConn wire lug connectors. The process consists of pigtailing using a setscrew type wire lug instead of a COPALUM crimp connector. This process must be applied to all direct aluminum wire connections to copper wiring devices, electrical equipment and light fixtures.

CPSC also highly recommends that you DO NOT address your home aluminum wire problems with the following methods as a permanent solution:

- DO NOT USE common

hand crimped connectors. - DO NOT PIGTAIL with any hand twist-on wire nut connectors.

These two methods are often recommended by some electricians, as they tend to be significantly cheaper alternatives. However, most crimped and wire nut connectors are not designed to address the overheating problems presented by Aluminum wires at the electrical device’s connections.For additional information on how to effectively and permanently repair your Aluminum wire problem..

Pros Of Performing An Aluminum Wiring Remediation

Understandably, there are some people who may wonder whether replacing all their aluminum wiring is really a benefit, since at the outset it might seem like a costly investment. It is important to remember, however, that the health and safety of your family, friends, colleagues, or anyone else visiting your property is always the highest goal. Replacing your aluminum wiring will lower the risk of fires and electrical shock.

In addition to this critical advantage, however, there are other significant benefits as well, including:

- Smoother, more efficient conductivity with copper wiring.

- Less crowded electrical networks since copper takes up less space.

- Higher amount of durability and strength.

- Drastically decreased risk of melting or catching fire

XXXXX

I am David, economist, originally from Britain, and studied in Germany and Canada. I am now living in the United States. I have a house in Ontario, but I actually never go. I wrote some books about sovereign debt, and mortgage loans. I am currently retired and dedicate most of my time to fishing. There were many topics in personal finances that have currently changed and other that I have never published before. So now in Business Finance, I found the opportunity to do so. Please let me know in the comments section which are your thoughts. Thank you and have a happy reading.